.png)

Next generation LPBF system for multimaterial rocket parts

Project

Goal

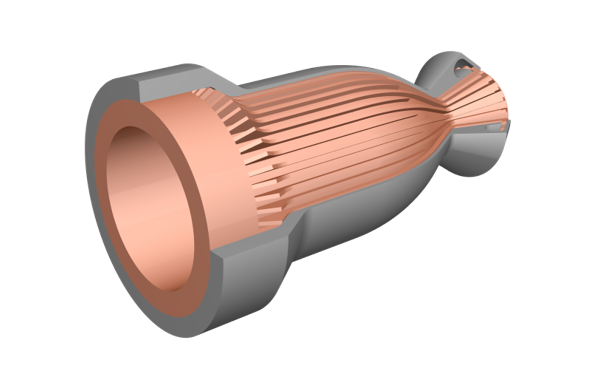

Additive Manufacturing, especially Laser powder bed fusion, is a relatively young technology with a fast-growing market across many industries. It allows for the manufacturing of parts with a complexity that cannot be achieved in any other way. This complexity allows engineers to better utilise materials and design higher performing components. RAPTURE wants to take the next step and increase this level of performance even further through multi-material capability, which allows multiple materials to be used in one component. With a newly developed recoating method we aim to build the fastest and most powder conserving system to date.

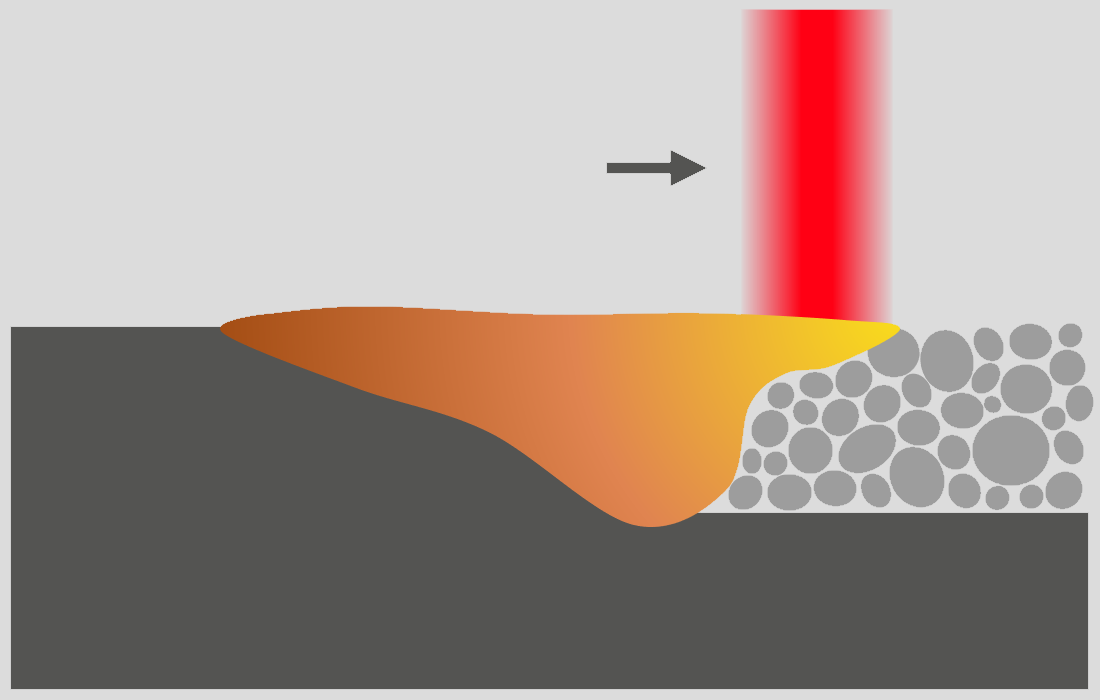

LPBF

Laser Powder Bed Fusion (LPBF) is an advanced 3D printing technology used in additive manufacturing. It involves the layer-by-layer deposition of fine metal or polymer powders, which are selectively melted using a high-powered laser. LPBF creates complex, precise, and fully functional 3D objects with exceptional detail and material properties. This process offers design freedom, reduced waste, and the ability to produce intricate, customized parts for industries such as aerospace, healthcare, and automotive. LPBF has revolutionized manufacturing by enabling rapid prototyping and cost-effective production of components with superior strength and performance.

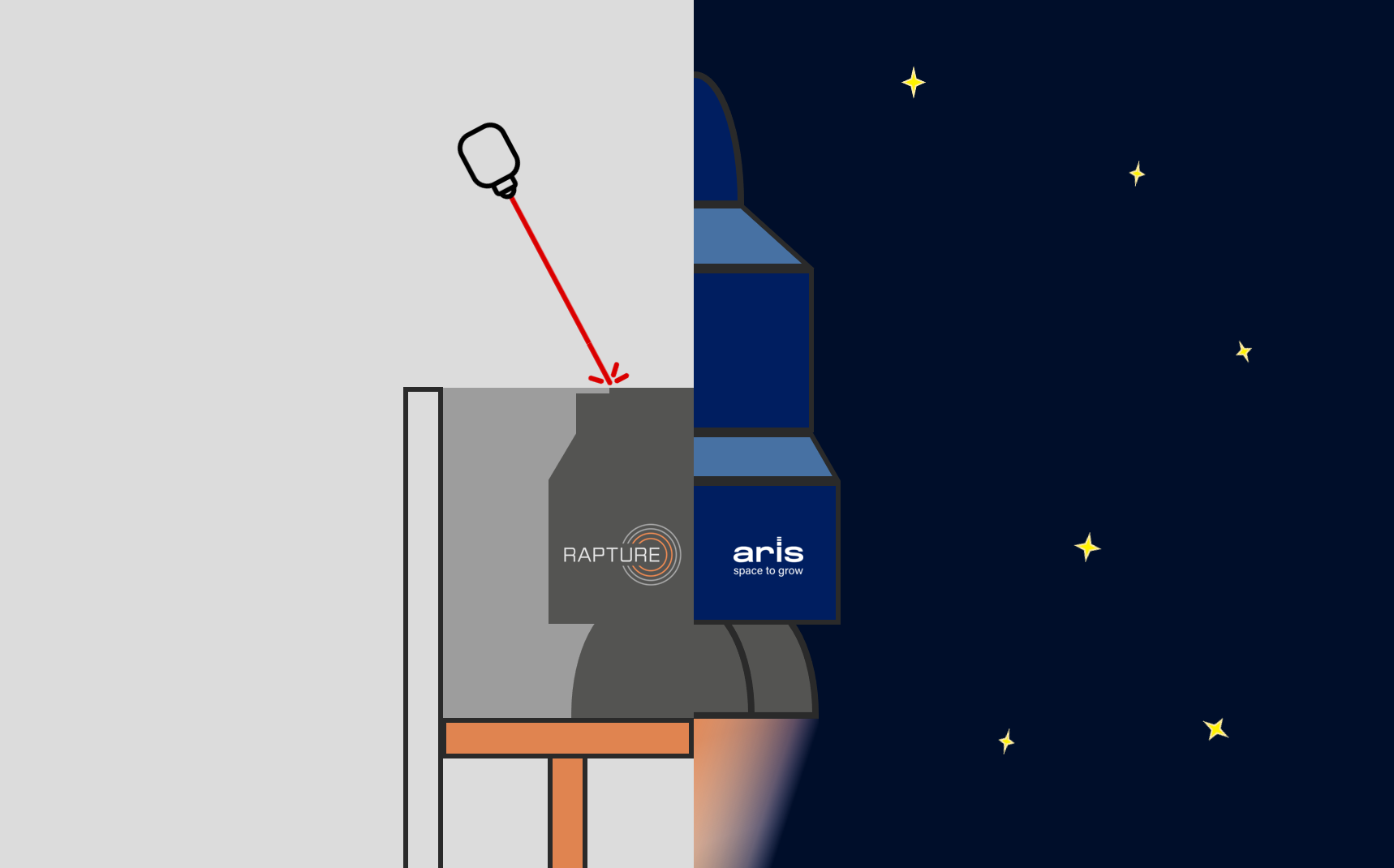

Aerospace

Multi-material LPBF is promising for rocket applications as it enables the integration of various materials in a single part. This capability streamlines the design of lightweight, high-strength components, optimizing performance while reducing weight. In rocketry, where efficiency is critical, multi-material LPBF offers the flexibility needed to create specialized components, such as heat shields and nozzles, each with tailored material properties. This technology promises to enhance the reliability and performance of rocket systems, making it a valuable advancement in the aerospace industry.

Background

RAPTURE is a Focus Project at the Swiss Federal Institute of Technology (ETH) in Zurich under the Department of Mechanical and Process Engineering (D-MAVT). Enthusiastic students get an exclusive opportunity to learn-by-doing by working in a small team during their last academic year of the bachelor curriculum. The team conducts all aspects of product development whith the support of their academic supervisors and industry professionals. Furthermore, Project RAPTURE is part of the Academic Space Initiative Switzerland (ARIS), which brings together students from Swiss universities to pursue space exploration. This project builds upon the success of the 2022-2023 Focus Project PROMETHEUS , which developed a test bed for additively manufactured liquid-fuled rocket engines.

Machine Impressions

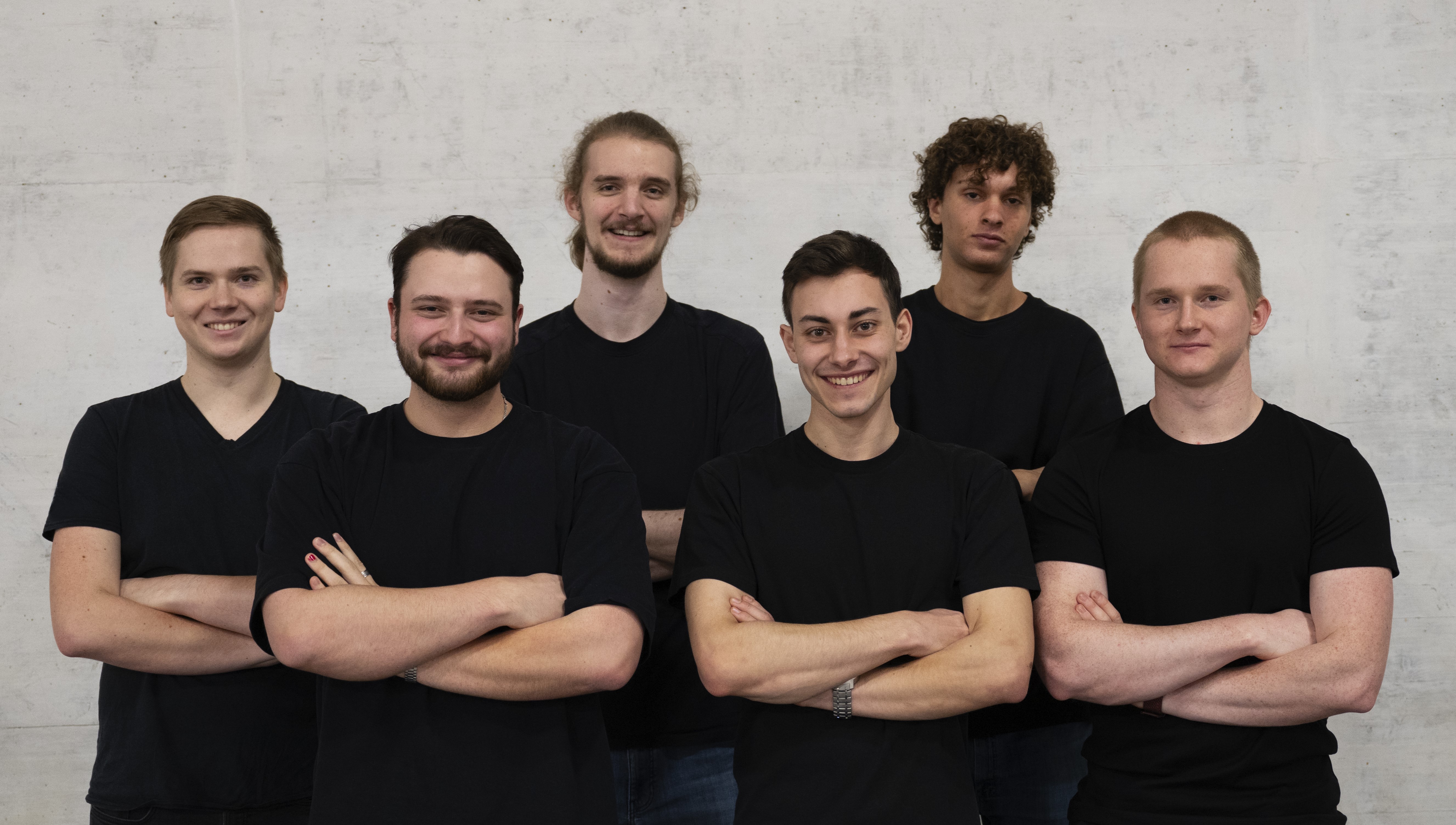

Team

Engineers

Experts

Prof. Dr. Markus Bambach

Dr. Michael Tucker

Fiona Konnerth

Raphael Steffen

Sponsors

Academic Partners

Industrial Benefactors

To support us in our technical and educational mission, we’re looking for sponsors. We are happy to accept financial support, in-kind donations of materials, parts, or services, technical consultations, and more. We would very much appreciate your help with realizing this revolutionary new technology! Please have a look at our sponsoring brochure or contact our Project Manager Patrick Moser for more information on how you or your company can be a part of Project RAPTURE.

.....

.....

Gold

Inconel

Copper

Patron

Contact

ETH Zurich

Focus Project RAPTURE

PFA F43 (1. Floor)

Technoparkstrasse 1

8005 Zurich

Switzerland

E-mail: mavt-amlz-rapture@ethz.ch

Office: +41 44 633 94 99

.png)

.png)

.png)

.png)

.png)